Material development and processing of CFRP and composite materials

Our company is based in Hekinan City, Aichi Prefecture, and specializes in cutting composite materials such as CFRP (carbon fiber reinforced plastic).

We have been involved for many years in manufacturing high-precision parts that take advantage of CFRP's properties such as light weight, high strength, vibration absorption, and low thermal expansion in fields such as aerospace, automobiles, industrial robots, precision machining equipment, and assembly processing equipment.

We also provide the following services regarding materials.

1. Material design: We respond to requests by carrying out material design and processing based on consultations regarding the strength direction and usage environment according to the request.

2. Material development: We are also conducting research and development of composite materials, including CFRP, which is expected to be used in a variety of fields in the future.

| Address | |

|---|---|

| Phone Number | 0566708481 |

| URL1 | https://www.kyowa-tokai.com/ |

| URL2 | https://www.instagram.com/warabon414/ |

| URL3 | https://x.com/acftf1cbtjwlwyj?lang=ja |

Product / Service

Drone CFRP parts: auxiliary materials for vibration control of the aircraft

In drones and flying cars, vibrations transmitted through the frame can significantly degrade the performance of the precision equipment installed inside.

To address this issue, Kyowa Seisakusho has developed washers and spacers made from CFRP, NFRP, and composite sandwich plates, which boast excellent vibration damping performance.

By attaching these auxiliary materials to the frame, unnecessary vibrations are effectively absorbed and damped, protecting the precision equipment and improving the aircraft's flight stability.

CFRP "Ribs" (for aircraft, VTOL drones, and flying cars)

"Ribs" are important structural components that shape the wings and body of aircraft, VTOL (vertical take-off and landing) drones, and flying cars, protecting them from the great forces they face in the air.

At Kyowa Seisakusho, we use CFRP for these ribs, offering a solution that improves aircraft performance to an unprecedented level, something that was difficult to achieve with conventional metal ribs.

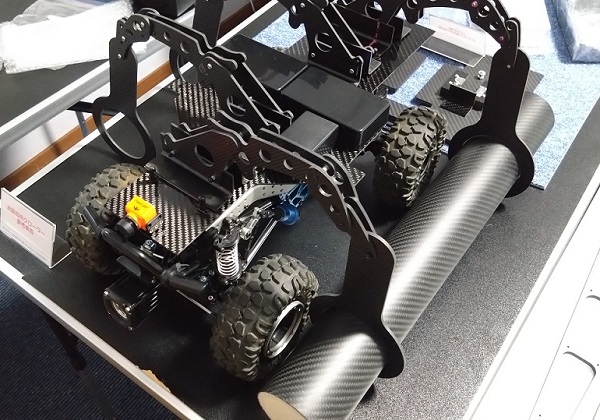

Unmanned small amphibious crawler prototype parts

"Crawler" is a small, amphibious unmanned robot expected to be useful at disaster sites.

We have developed an unprecedented prototype part that combines CFRP pipe, which can be used in any disaster, with special urethane.

The special urethane provides incredible buoyancy and impact resistance,

while CFRP offers overwhelming lightness and reliable strength.

We have combined the advantages of these multiple materials using our unique composite processing technology.

Please come and see this technology that greatly expands the possibilities for disaster relief.

Details of the CFRP pipe filled with special urethane will be announced at the exhibition.

Download

2. Excellent vibration resistance, sound damping, and light weight

3. Impact resistance and improved structural stability

1. Surface, Underwater, and Aviation:

Marine survey equipment, amphibious crawlers, ship parts, floating robots,

Aircraft and amphibious flying boat parts

2. Disaster Prevention and Rescue Operations:

Survey equipment in flooded areas, lightweight and durable stretchers and transport devices,

Improved mobility and safety in harsh conditions

3. Industrial Equipment and Robots:

Improved performance and reliability for vibration-sensitive precision equipment housings, lightweight and high-speed robot arms, inspection equipment used in harsh environments,

4. Other:

Lightweight structural materials in the construction and civil engineering fields, sports and leisure goods, etc.

The properties of composite materials offer significant benefits, particularly in parts such as washers, spacers, and separators.

1. Excellent vibration absorption for high precision and quiet operation.

2. Lightweight yet strong, with outstanding specific compressive strength.

3. Durability and corrosion resistance that withstand harsh environments.

4. Heat resistance and low thermal expansion rate, essential for precision machinery.

- Resistant to temperature changes! "Shape stability" firmly maintains the wing shape

- Tough even with repeated use! "Long-lasting strength" increases reliability

- Firmly maintains the ideal wing shape! "Shape retention" maximizes performance

- Transmits force effectively, yet lightweight! "Efficient load transfer" and "Lightweight" are both achieved

- Resistant to twisting for stable flight! Excellent "torsional rigidity"