Provision of metal precision machined parts with dimensions of 200x200x200.

Our company was founded in 1898 (Meiji 31) as a manufacture of pocket watch components, and since then, we have consistently delivered precision metal processing parts focusing on small components, always using the latest equipment and technology to ensure trust to our customers. Currently, we have CNC automatic lathes, small precision gear processing machines, high-speed machining centers, and presses, enabling us to provide integrated processing from materials to parts fabrication and assembly, as well as the design and manufacturing of all related tools and equipment, all as a one-stop service for 'Monozukuri' (manufacturing). We will continue to provide high-quality products that meet our customers' needs, along with speedy and reliable service.

| Address | |

|---|---|

| Phone Number | 0594226223 |

| URL1 | http://www.kuwanaseiko.co.jp |

| URL2 | https://www.instagram.com/kuwanaseiko/?hl=ja |

| URL3 | https://www.facebook.com/profile.php?id=100057252888662 |

Product / Service

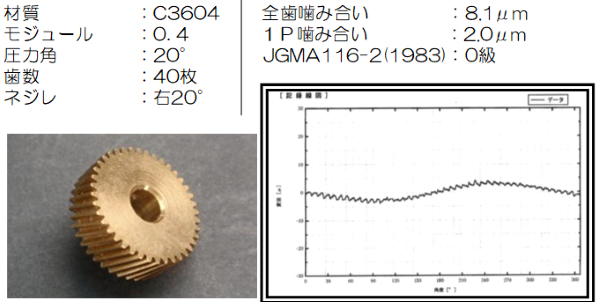

High-precision small module gear processing

With high-precision gear machining for modules of 0.2 to 1.0, it contributes to smooth rotation with low load.

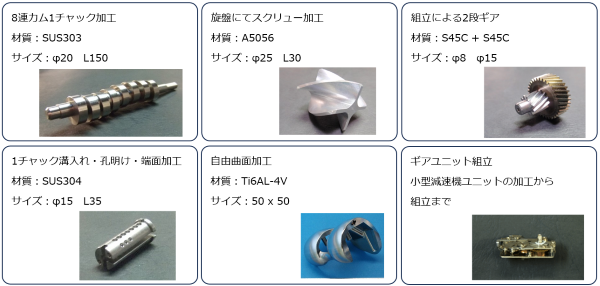

Complex Shape Metal Processing

Processing parts that fuse the 'freedom of shape' and 'precision of cutting'.

It is possible to process parts with complex shapes to high precision using our unique technology.

Others

・Complex shape processing

・Difficult-to-machine materials

・Assembly

Download

・History

・Owned Equipment

・Processing Examples, etc.